Overview

Services

Manufacturing Efficiency

, Production Management

, Quality Control

Approach

Observed factory workflow across departments — fabric, trims, sampling, cutting, sewing, finishing, and dispatch.

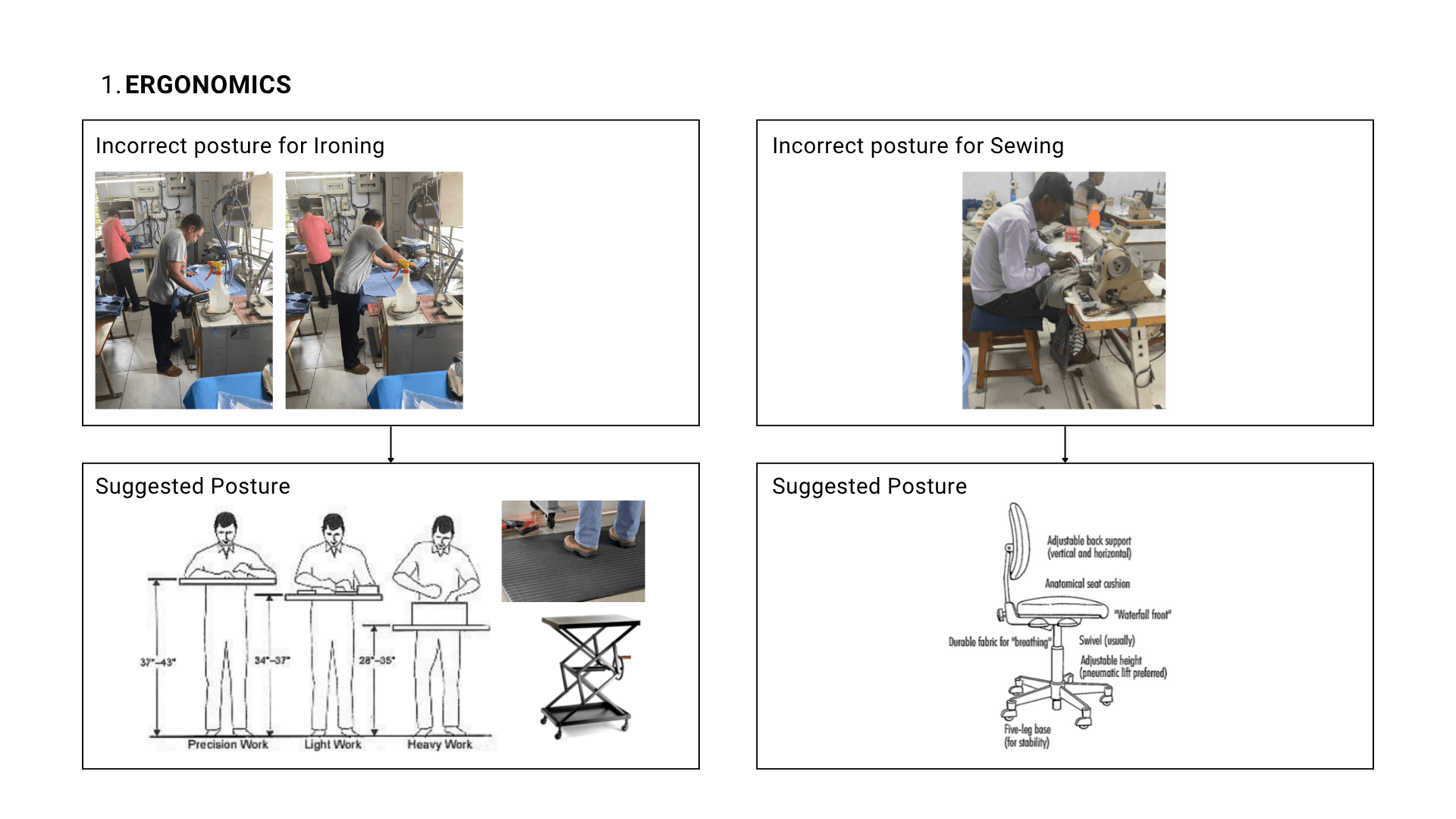

Identified key inefficiencies: poor ergonomics, lack of inline inspection, and bottleneck operations (e.g., sleeve-making).

Applied industrial engineering concepts to propose solutions like ergonomic seating, improved sewing layout, and inline quality checkpoints.

Executed two live projects:

Traffic Light Inspection System → early defect detection and operator accountability.

5S in Store Room → organization, cleanliness, and material handling.

outcomes and impact

Implemented 5S methodology and Traffic Light Inspection System, enhancing efficiency by 12.5% and reducing defect rates by 18%. Offered a long-term framework for scaling quality and operational efficiency while maintaining a productive environment.